Non-Metallic Liner Inspection on Type IV Cylinder with Terahertz

Application – Sub-Surface Defects on GFRP Samples(Type IV Cylinder)

What are Type IV cylinders?

Type IV cylinders are advanced, high-pressure gas storage vessels designed primarily for applications involving compressed natural gas (CNG) and hydrogen. These cylinders are constructed with a plastic (polymer) liner that is fully wrapped with composite materials, typically carbon fiber or a carbon/glass fiber blend. This unique design results in a cylinder that is significantly lighter than traditional steel or aluminum options, without compromising on strength or safety.

The lightweight nature of Type IV cylinders makes them ideal for use in automotive and aerospace industries, where reducing weight translates to improved fuel efficiency and performance. Additionally, their non-metallic liner provides excellent resistance to corrosion, enhancing durability and reducing long-term maintenance costs. Type IV cylinders also offer high energy storage capacity, making them well-suited for mobile and stationary fuel storage systems.

Their design and efficiency support the transition to cleaner fuels and play a key role in sustainable energy solutions.

Applications of Type IV Cylinders

Type IV composite cylinders are ideal for high-pressure gas storage across various industries due to their lightweight and high-strength design.

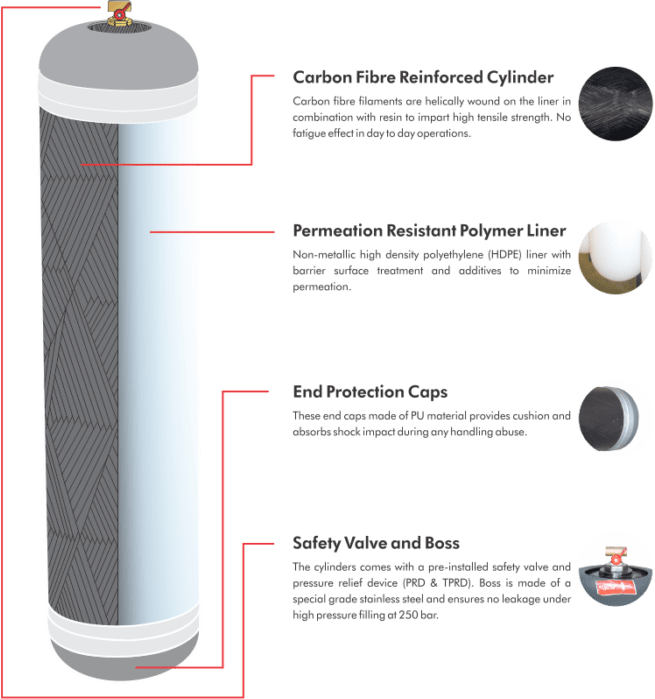

Type IV Cylinders materials:

Materials Used in Type IV Cylinders

Type IV cylinders are made using advanced lightweight and high-strength materials:

- Liner:

– Plastic (Polymer) – typically HDPE (High-Density Polyethylene) or Nylon

– Acts as a gas-tight inner shell and prevents corrosion - Composite Wrap:

– Carbon Fiber – for high strength and lightweight performance

– Glass Fiber (optional) – to reduce cost while maintaining strength

– Epoxy Resin – to bind fibers and provide structural integrity

Boss (Valve Area):

– Aluminum or Stainless Steel – used to connect valves and fittings securely

Terahertz Testing Benefits for Type IV Cylinders

- Delamination Detection

Identifies separation between composite layers (carbon/glass fiber and liner) without damaging the cylinder. - Void & Inclusion Inspection

Detects trapped air pockets, resin-rich zones, or foreign materials inside the structure. - Liner Integrity Assessment

Evaluates the plastic liner (HDPE/Nylon) for cracks or material degradation over time. - Thickness Measurement

Measures wall thickness of both the composite wrap and liner with high accuracy. - Moisture and Defect Mapping

Maps internal moisture content and micro-defects that could lead to long-term failure. - Non-Contact & Safe

Uses non-ionizing radiation—safe for operators and ideal for sensitive material inspection.

PROPOSED SOLUTION:

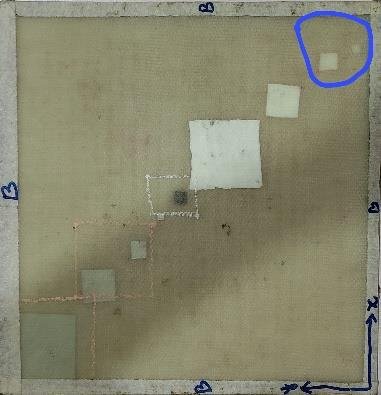

Due to its complex design and manufacturing process, it is susceptible to various internal defects and damages, voids and delamination. In the below GFRP sample, we have embedded with external materials such as Aluminum, mild steel and Teflon tape.

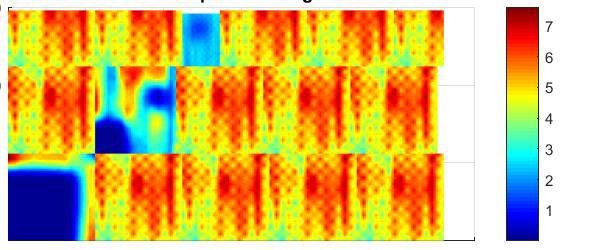

(a) Visible image of GFRP sample with Aluminium, mild steel and teflon inserts (b) THz image of GFRP sample (marked area)

The imaging can be done with TeraNIM device and Probe Head. The entire image has been obtained by calculating the average intensity at each pixel. The Aluminium inserts have been clearly shown as mentioned in the figure. Teflon tape and GFRP samples have similar transmission intensity and hence has not been imaged in this figure. Walter et al. has utilized the THz-TDS system to detect, localize and evaluate hidden multi-dimension effects in multilayered GFRP structures as shown in Figure 3.

Conclusion:

Terahertz Technology is capable of testing Non-Metallic liners on CFRP Type IV Cylinder for Thickness, Voids, Inclusions, CFRP-GFRP Bonding, Delamination and Material Properties (effective refractive index and absorption coefficients).