Lead-Acid Battery Vent Cap Inspection

Non‑contact, Non‑destructive Testing of Hidden Vent Caps in Sealed Automotive Batteries

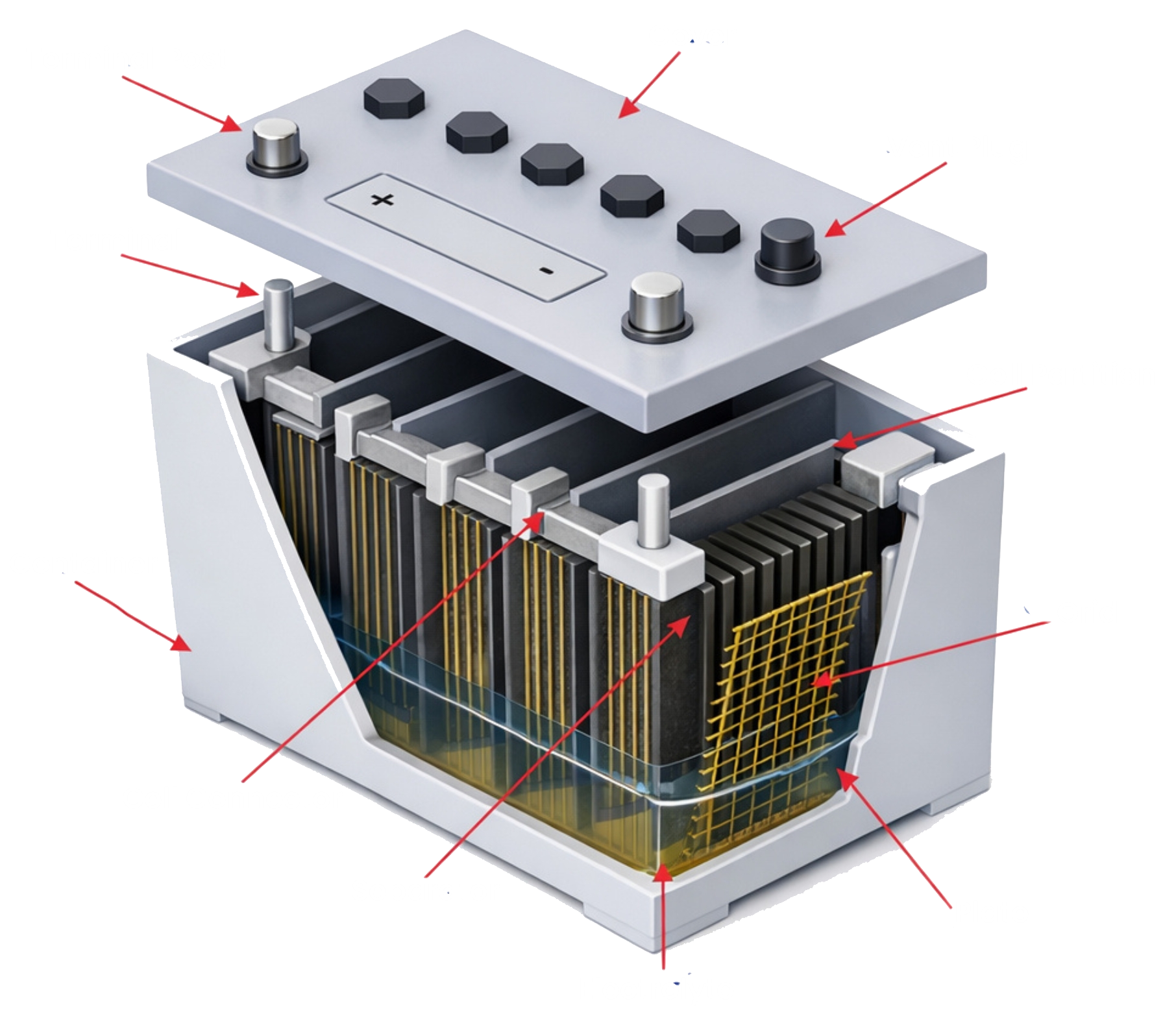

In automotive lead-acid battery manufacturing, vent caps are critical for safe pressure regulation and gas release. Once assembled, these vent caps are sealed beneath plastic covers, making conventional inspection methods ineffective. TeraLumen’s terahertz inspection technology enables reliable subsurface verification of vent cap presence without disassembly, surface preparation, or production disruption.

Traditional Inspection & Challenges

Visual Inspection

Limited to pre-assembly stages, once the battery cover is sealed, direct visual confirmation of vent cap presence is no longer possible.

Terahertz Inspection Workflow

Direct a terahertz pulse onto the sealed battery surface (single-side access).

Capture reflections from internal interfaces—plastic, air gaps, and vent cap features

Extract signal features and classify: vent cap present vs missing (automation-ready).

THz Inspection Results & Key Advantages

- Clear identification of acceptable and defective assemblies

- Single-side, non-contact inspection through plastic covers

- Reliable detection of vent caps beneath sealed covers

- Non-destructive and non-ionizing inspection method

- Automation-ready for inline production inspection

Conclusion

TeraLumen’s terahertz inspection technology provides a production-ready solution for verifying vent cap presence in sealed automotive battery assemblies. By enabling subsurface inspection where conventional methods fail, manufacturers can improve safety, reduce rework, and ensure consistent product quality.

Solution With

Lead-Acid Battery Vent Cap Inspection

Non-contact, non-destructive Testing of hidden vent caps in sealed automotive batteries.

In automotive lead-acid battery manufacturing, vent caps are critical for safe pressure regulation and gas release. Once assembled, these vent caps are sealed beneath plastic covers, making conventional inspection methods ineffective. TeraLumen’s terahertz inspection technology enables reliable subsurface verification of vent cap presence without disassembly, surface preparation, or production disruption.

Traditional Inspection & Challenges

Visual Inspection

Not possible once the battery cover is sealed.

Mechanical Probing

Risk of component damage or misalignment.

Weight-Based Checks

Unreliable due to manufacturing tolerances.

X-ray Inspection

High cost, safety concerns, and limited plastic contrast.

Destructive Inspection

Sample-based only and unsuitable for routine QC.

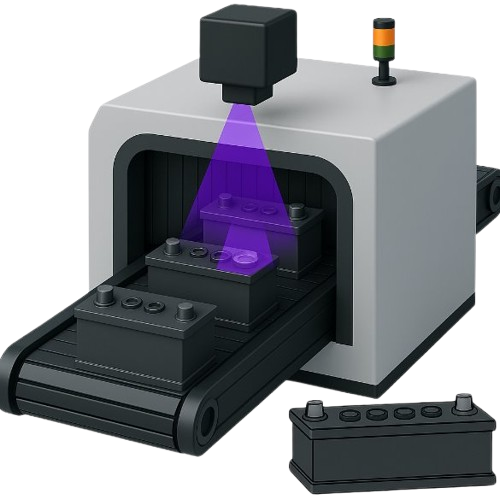

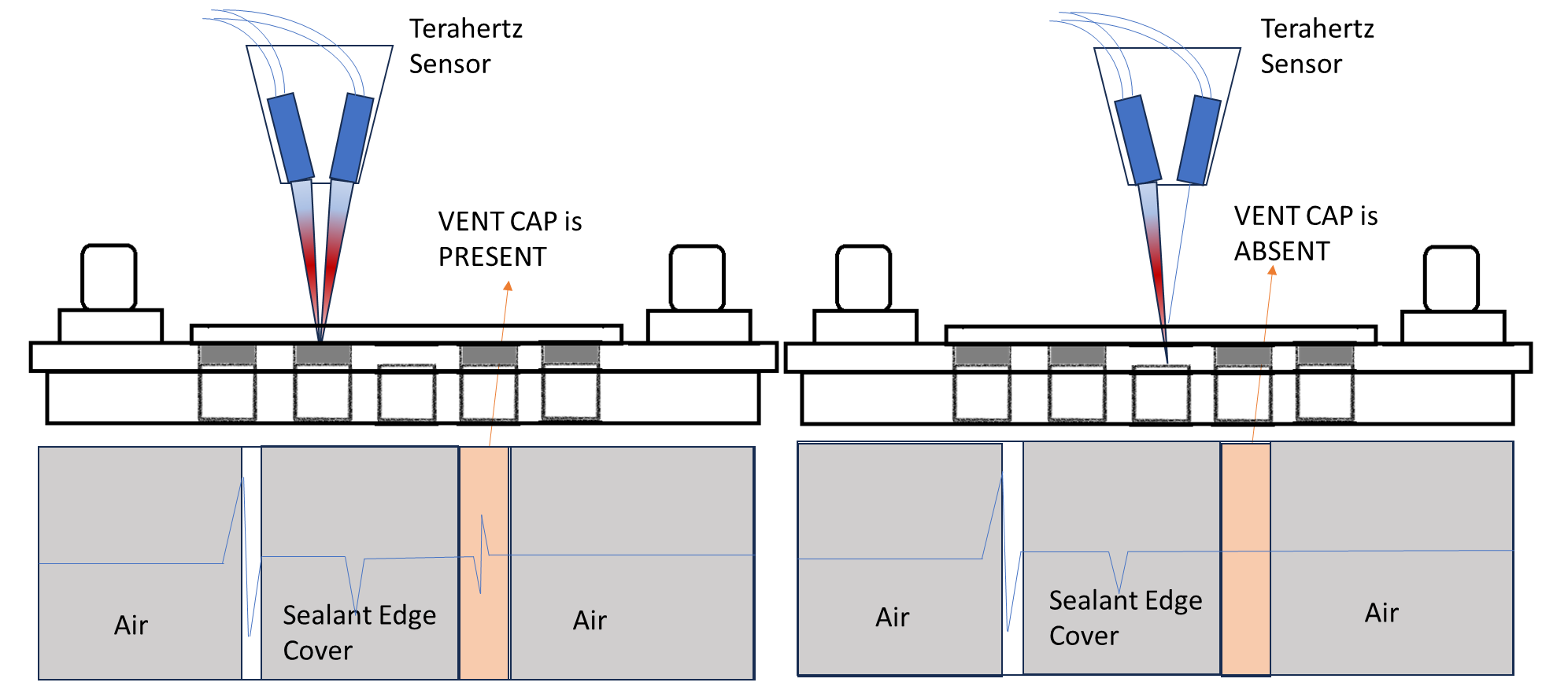

Terahertz Inspection Workflow

Direct a terahertz pulse onto the sealed battery surface (single-side access).

Capture reflections from internal interfaces—plastic, air gaps, and vent cap features

Extract signal features and classify: vent cap present vs missing (automation-ready).

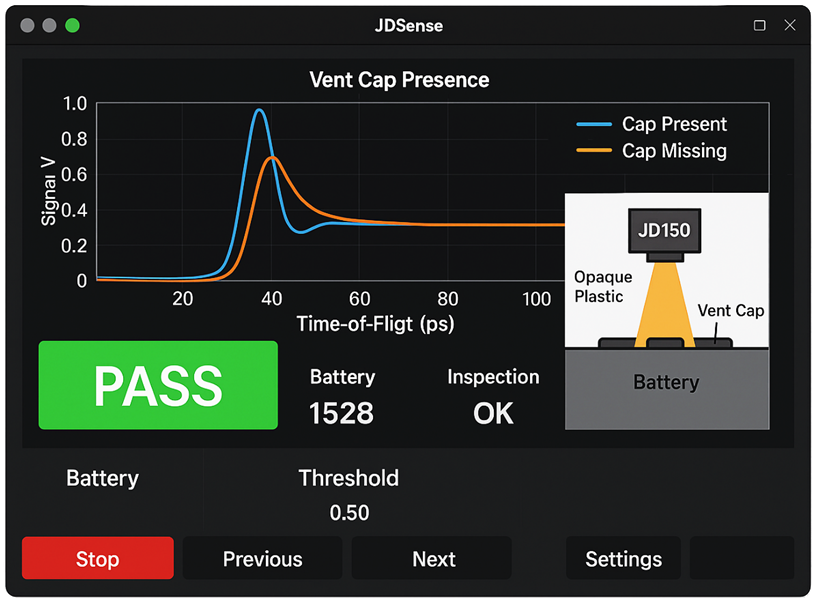

THz Inspection Results & Key Advantages

- Clear identification of acceptable and defective assemblies

- Single-side, non-contact inspection through plastic covers

- Reliable detection of vent caps beneath sealed covers

- Non-destructive and non-ionizing inspection method

- Automation-ready for inline production inspection

Conclusion

TeraLumen’s terahertz inspection technology provides a production-ready solution for verifying vent cap presence in sealed automotive battery assemblies. By enabling subsurface inspection where conventional methods fail, manufacturers can improve safety, reduce rework, and ensure consistent product quality.